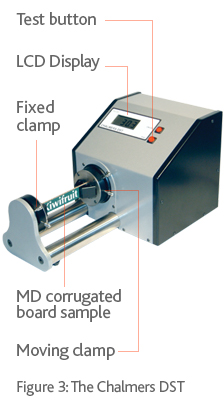

The Chalmers DST (Dynamic Stiffness Tester) measures the MD torsional stiffness of corrugated board by a natural oscillation technique which was patented by Korutest in 2005. Using this method the board is subjected to a displacement and allowed to oscillate freely. The frequency of this oscillation is directly proportional to the torsional stiffness of the sample. The stiffer the sample, the higher the frequency.

The corrugated board sample is cut 25 mm wide along the machine direction (across the flutes) and 148 mm in the cross machine direction. The sample is placed in the self centering clamps and the Test button pressed. After four oscillations the result is displayed on the LCD screen. A USB port allows direct coupling to a computer for data collection.

A knife guide made from a 6mm thick steel plate with a handle is supplied with the DST. This guide allows the use of a Stanley type knife to cut samples on the spot. A blade thinner than 0.45 mm (Stanley 1991) is required for the cutter. Some customers use modified Billerud ECT cutters, single blade slicing type cutters, laser or even X-Y plotter type sample cutting tables.

The DST can be used right next to the machine providing real time data to the operators. This data can also be captured and directed to a mill-wide MIS system. As well as having a dedicated DST to monitor corrugated grade changes, many of our customers have placed their second DST on a trolley so that the tester can be easily moved around the plant – taking readings from different converting machines, ensuring quality at every stage of the production process.

The DST is supplied with a USB cable and device recognition software. Free Windows HyperTerminal software can be used for downloading data or if that is not available we recommend WinWedge a reasonably priced piece of software from TalTech.com. WinWedge allows you to enter results directly into an Excel spreadsheet.